What is a ball valve and how do they work?

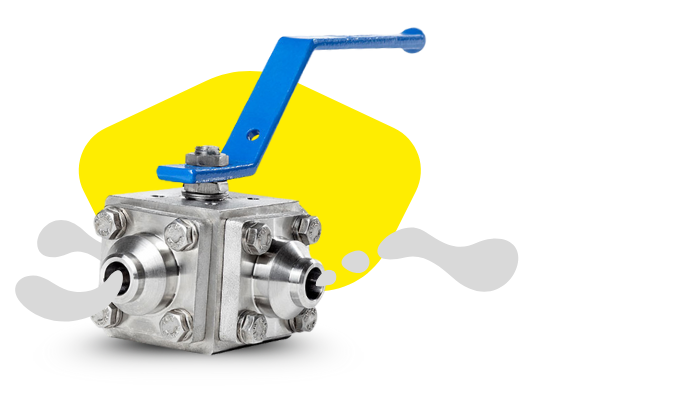

A ball valve is a shut-off valve that regulates the flow of liquids or gases using a rotating ball. When the ball is turned 90 degrees, it opens or closes the flow. This makes the ball valve a popular choice for fast and reliable flow control in everything from water and oil pipes to industrial systems.

Which type should you choose?

There are different types of ball valves, and the choice depends on how you want to control the flow.

Ball valve 2-way – The most common type, with an inlet and an outlet. Perfect when you just need to open or close a feed.

Ball valve 3-way – Has three ports and is used when you want to direct the flow in different directions, such as switching between two pipes or mixing different liquids.

In addition to this, there are also differences in materials and construction. Should the valve be able to withstand high pressures and temperatures? Then carbon steel or a stainless steel variant can be a good choice. For more demanding environments, advanced materials such as Super Duplex are available, while a brass valve works great in simpler applications.

How to find the right ball valve

To make a good choice, you need to think about the following.

- Which medium should flow through the valve – water, oil, gas or chemicals?

- Pressure and temperature – some materials can withstand more than others.

- Sealing material – PTFE seals provide good durability, while metal seals can withstand extreme conditions.

- Flow control – Do you only need an on/off function, or do you want to control the flow in multiple directions?

Common mistakes to avoid

Many people choose the wrong ball valve by

- Not adapting the material to the medium.

- Underestimate the importance of the right sealing solution.

- Forget to check pressure and temperature limits.

- Fail to inform about important certificates and documentation that are required.

- Do not specify whether the valve should be automated or operated manually.

Find the right ball valve for your application

Choosing the right ball valve is all about understanding your specific needs and ensuring a model that delivers both performance and durability. A well-matched ball valve can improve operational reliability, reduce maintenance and optimise flow control in your facility.

At Axel Larsson, we offer a wide range of ball valves in different materials and designs, carefully adapted for both industrial and commercial applications.

Do you have questions or are unsure which model is best suited? Our experts are here to help. Contact us today, and we will guide you to a solution that is both effective and long-term.